H2S Scavengers

Remove Sulfur From Your Gas or Liquid Hydrocarbon Stream

Contact SEPCOR today to discuss how we can help your company with our proven products and solutions!

Products & Features

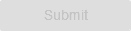

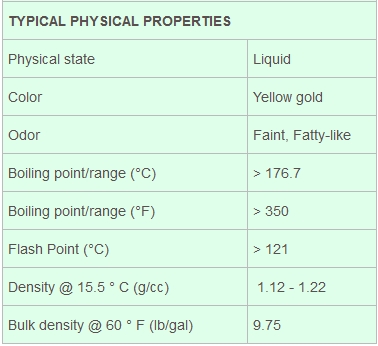

SEPCOR SE-100 H2S Hydrogen Sulfide Scavenger

SE-100 H2S is a proprietary formulation designed to remove hydrogen sulfide (H2S) from production systems. SE-100 H2S will react with H2S (sour gas) to form stable, water-soluble reaction by-products that may be easily removed from the system.

SE-100 gives an economical means for removal of hydrogen sulfide. SE-100 H2S can be used in many methods of treatment. It can be very easily utilized by:

- Contactor towers through which sour gas percolates.

- Well head transmission lines using injection pumps. SEPCOR, Inc. SE-200 H2S Hydrogen Sulfide Scavenge

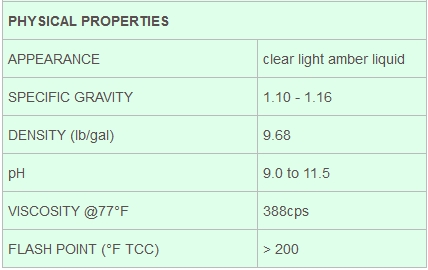

SEPCOR SE-200 H2S

SEPCOR SE-200 H2S is a proprietary formulation designed to remove hydrogen sulfide (H2S) from production systems. It is oil dispersable and soluble in water. It is specially formulated for use in drilling applications and fluid hydrocarbon systems. SE-200 H2S will react with H2S forming stable, water-soluble reaction by-products that may be easily removed from the system.

CUSTOMER BENEFITS:

Gives an economical means for removal of hydrogen sulfide. SE-200 H2S can be used in many methods of treatment. It can be very easily utilized by:

- Drilling Muds

- Oil Pipelines

- Storage Tanks

- Transfer Lines

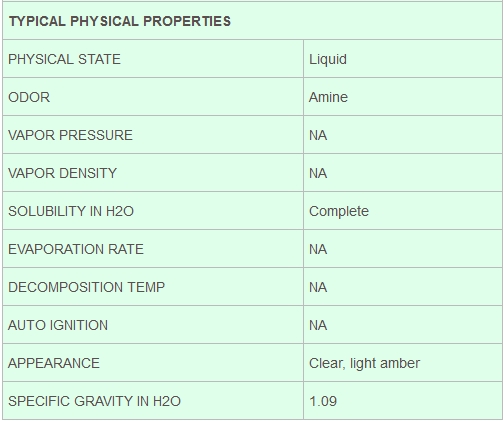

SE-300 H2S-OilSolve

SE-300 H2S-OilSolve is a solvent-based, oil soluble, liquid formulation designed to remove hydrogen sulfide (H2S) and mercaptans from oils and crude. Enviro-Solve 105 reacts with H2S even at elevated temperatures (260◦F) to

effectively remove the unwanted sulfur.

SE-300 H2S-OilSolve may be injected into pipe lines or mixed with crude oil and hot bitumens. Applications are in situations

where it is important to minimize water contamination of the treated stream. Carrier solvents will blend into the treated.

SEPCOR SE-400

SEPCOR SE-400 is an H2S scavenger for fluids that require an oil soluble scavenger.

SEPCOR SE-400 has been formulated to maximize the activity while maintaining fluidity.

Applications:

It is recommended that SEPCOR SE-400 be injected into the gas or fluid that needs to be treated. Several industries employ SEPCOR SE-400 for their H2S removal needs such as oil and paper. Application procedures by industry are available upon request. Dosages anticipated are 0.06 gal to 0.08 gal per ppm H2S per 100 barrels or 0.08 gal to 0.10 gal per ppm H2S per MMSCF.

- Removal of H2S & mercaptans

- Effectively removes H2S from oil and asphalt

- Safe water soluble reaction product

- Minimal Capital Investment

- No Disposal

SEPCOR SE-HT

SEPCOR SE-HT is a proprietary formulation designed to remove hydrogen sulfide (H2S) from high temperature systems. SEPCOR SE-HT will react with H2S to form reaction by-products.

APPLICATION:

SEPCOR SE-HT is applical for downhole applications where temperatures are at elevated temperatures up to 400 degrees F. This chemical is stable at such temperatures and will continue to react with H2S forming stable salts. Applicable in above ground storage tanks and transfer lines for gas phase systems and liquid hydrocarbon systems like asphalt tanks.

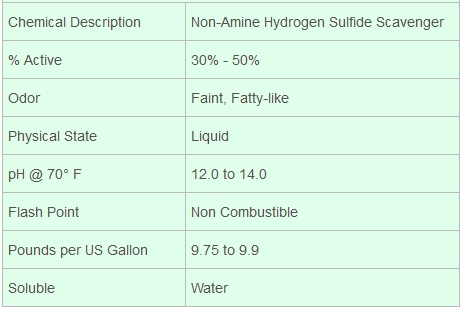

SEPCOR 100X NON-AMINE HYDROGEN SULFIDE SCAVENGER

SEPCOR 100X is a clear to amber liquid with no discernable odor. It does not contain nitrogen or heavy metals. It is non-flammable, nonreversible and removes H2S instantly upon contact. Formulated to remove hydrogen sulfide (H2S) from crude oil streams.

Winterized and Custom formulations based on this product can be blended to meet customer finished product requirements. The efficiency of SEPCOR 100X is far superior to traditional scavengers will depend on factors such as contact time, pressure, temperature, mass transfer and other variables.

While SEPCOR100X has many applications, the most beneficial is to treat crude oil streams destined for a refinery. The non-amine base of this chemistry is extremely desirable to the refineries for the protection of equipment, particularly the crude unit also known as the atmospheric tower, where severe damage to the top of the tower can be caused by crude oil streams that has been treated with amine based chemistry.

High Scavenge Rate, Low Foaming, Wide Temperature Range Sulfur Scavengers for Liquids and Gases

Subscribe

Keep up with current news by subscribing to SEPCOR's Quarterly Newsletter.

Contact us

2500 CityWest Blvd., Suite 300, Houston, Texas 77042

281-752-7272

info@sepcor.com

Ask About Our Solutions